In today’s competitive manufacturing landscape, maintaining impeccable quality control is more critical than ever. Companies strive to minimize defects, reduce waste, and ensure that every product leaving the line meets stringent standards. Enter machine vision—a technology revolutionizing quality control by automating inspection processes and overcoming many traditional challenges. At Sciotexe, we explore how mastering quality control challenges using machine vision can significantly improve productivity, accuracy, and cost-efficiency.

Understanding Machine Vision in Quality Control

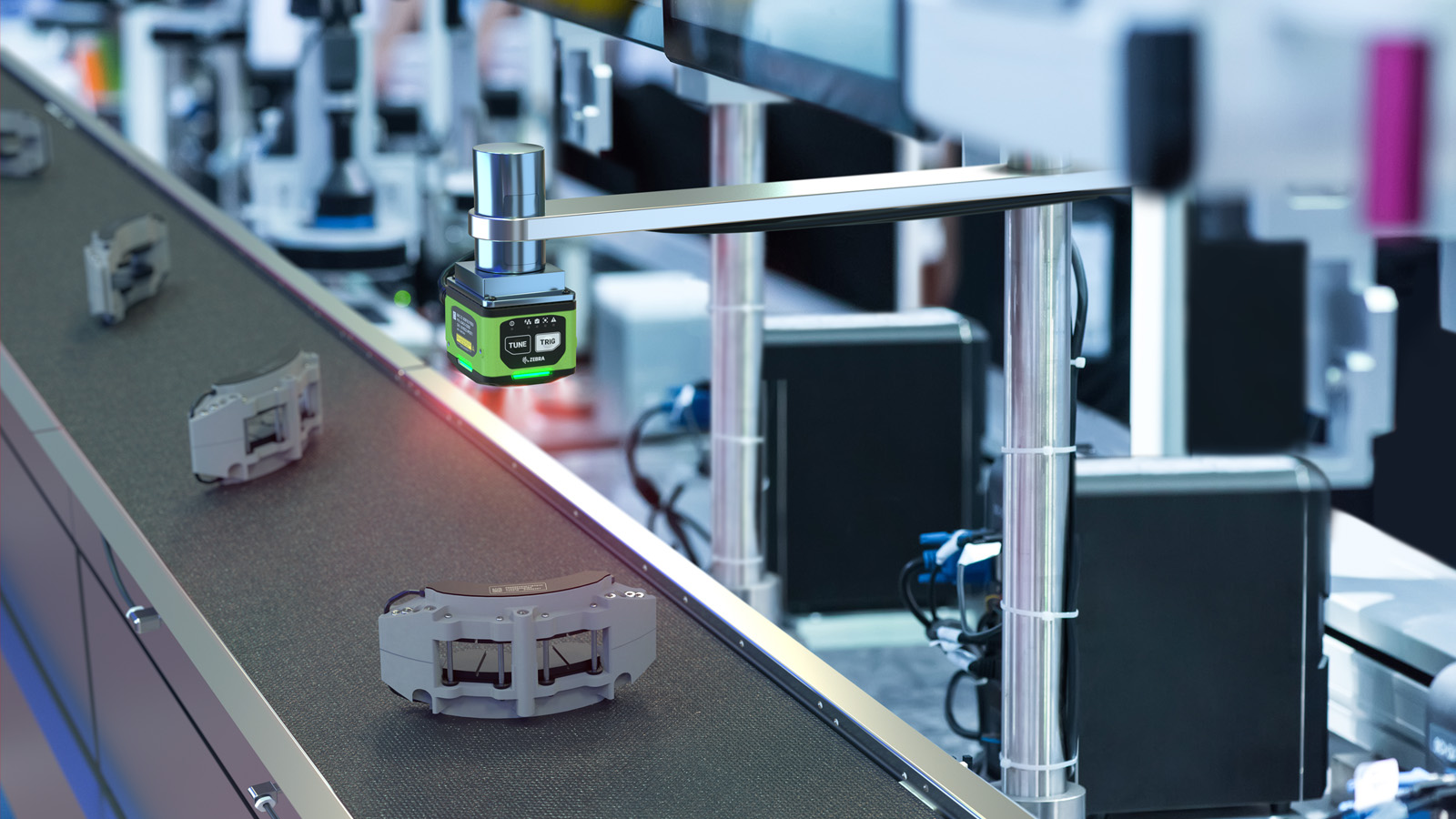

Machine vision refers to the use of cameras, sensors, and computer algorithms to capture, analyze, and interpret images for inspection and decision-making in industrial environments. Unlike human inspectors, machine vision systems can operate 24/7 without fatigue, delivering consistent and precise evaluations.

By integrating machine vision into quality control, manufacturers can detect defects, measure dimensions, verify assembly, and even analyze surface textures—all in real-time. This automation not only accelerates the inspection process but also enhances the reliability of results, reducing the risk of faulty products reaching customers.

Key Quality Control Challenges in Manufacturing

Before diving deeper into the advantages of machine vision, it’s essential to identify the core challenges faced in quality control:

- Human Error and Inconsistency: Manual inspections are prone to fatigue, distraction, and subjective judgment, leading to inconsistent results.

- High Inspection Speeds: As production lines accelerate, maintaining thorough inspection without slowing down the process becomes difficult.

- Complex Defect Detection: Some defects are microscopic, subtle, or irregularly shaped, making them hard to spot by the human eye.

- Data Collection and Analysis: Gathering and processing quality data manually can be time-consuming and error-prone.

- Cost Constraints: Maintaining quality control with manual labor can increase operational costs and reduce profitability.

How Machine Vision Overcomes Quality Control Challenges

1. Enhanced Accuracy and Consistency

Machine vision systems use high-resolution cameras and advanced image processing algorithms to detect defects with remarkable accuracy. Unlike humans, these systems do not suffer from fatigue, ensuring that every inspection is consistent regardless of production volume or shift length.

2. Real-Time, High-Speed Inspection

One of the biggest hurdles in quality control is keeping pace with high-speed production lines. Machine vision can inspect hundreds of products per minute without sacrificing thoroughness. This capability ensures that manufacturers do not have to compromise between speed and quality.

3. Detection of Complex and Subtle Defects

Machine vision leverages sophisticated pattern recognition, 3D imaging, and hyperspectral analysis to detect even the most subtle defects invisible to human inspectors. This includes tiny scratches, color inconsistencies, surface deformations, and assembly errors.

4. Automated Data Collection and Reporting

Machine vision systems automatically collect inspection data, which can be used for detailed analysis, trend tracking, and compliance reporting. This automation reduces manual data entry errors and provides valuable insights for continuous improvement.

5. Cost-Effective Quality Control

While the initial investment in machine vision technology can be significant, it quickly pays off by reducing labor costs, minimizing waste, and preventing costly product recalls. Long-term, machine vision offers a highly cost-effective solution to maintain superior quality standards.

Applications of Machine Vision in Quality Control

Machine vision’s versatility allows it to address a wide range of quality control challenges across various industries:

- Automotive: Inspecting weld seams, paint quality, and assembly correctness.

- Electronics: Detecting solder joint defects, component placement accuracy, and PCB inspection.

- Food and Beverage: Verifying packaging integrity, label accuracy, and product contamination.

- Pharmaceuticals: Ensuring capsule fill levels, packaging seals, and barcode verification.

- Textiles: Detecting fabric defects such as tears, stains, and weaving errors.

Implementing Machine Vision: Best Practices

To master quality control challenges using machine vision, manufacturers should consider the following best practices:

- Define Clear Inspection Goals: Identify the key defects or quality parameters to focus on.

- Select Appropriate Hardware: Choose cameras, lighting, and lenses that suit the specific application.

- Customize Software Algorithms: Tailor image processing and analysis algorithms to detect relevant defects accurately.

- Integrate with Production Systems: Ensure seamless data flow between machine vision systems and manufacturing execution systems (MES).

- Train Operators and Maintenance Teams: Provide comprehensive training for smooth operation and troubleshooting.

- Continuously Monitor and Optimize: Regularly review inspection results to refine system performance.

Future Trends in Machine Vision for Quality Control

As technology advances, machine vision continues to evolve with exciting new capabilities:

- Artificial Intelligence (AI) and Machine Learning: AI-powered vision systems learn from data to improve defect detection and adapt to new product variations.

- 3D Vision and Augmented Reality: These tools provide deeper inspection insights and assist operators in real-time.

- Cloud-Based Analytics: Remote monitoring and data analytics enable global quality control management.

- Collaborative Robots (Cobots): Integrating machine vision with robotics enhances automation flexibility.

Why Choose Sciotexe for Machine Vision Solutions?

At Sciotexe, we specialize in delivering cutting-edge machine vision solutions tailored to your unique quality control challenges. Our expertise ensures you harness the full potential of this technology to optimize production, reduce waste, and elevate product quality. Partner with us to future-proof your manufacturing quality control with smart, scalable machine vision systems.

Frequently Asked Questions (FAQs)

Q1: What is the main advantage of using machine vision for quality control?

A1: Machine vision offers superior accuracy, speed, and consistency compared to manual inspection, enabling manufacturers to detect defects early and maintain high-quality standards.

Q2: Can machine vision systems detect all types of defects?

A2: While machine vision can detect a wide variety of defects, its effectiveness depends on system configuration and application. Combining it with AI and advanced imaging technologies enhances defect detection capabilities.

Q3: How costly is it to implement machine vision for quality control?

A3: Initial investment varies by system complexity and scale, but machine vision typically reduces overall costs by minimizing labor, waste, and product recalls, leading to a strong ROI.

Conclusion

Mastering quality control challenges using machine vision is no longer an option but a necessity in modern manufacturing. With its unmatched precision, speed, and automation capabilities, machine vision transforms quality assurance into a streamlined, data-driven process that delivers consistent, high-quality products. At Sciotexe, we are committed to helping you implement and optimize machine vision solutions that meet your specific needs, ensuring your manufacturing line stays competitive and efficient in the evolving industrial landscape. Our website is your ultimate source of valuable information.