In the ever-evolving landscape of metal fabrication, innovation plays a pivotal role in enhancing productivity and quality. Among the latest advancements, the double layer roll forming machine has emerged as a game-changer, delivering unmatched precision and efficiency. If you’re in the market for a high-performance gear that can streamline your production process, understanding the advantages and workings of this machine is essential.

This article delves deep into the world of the Double layer roll forming machine, explaining why it has become an indispensable tool in modern manufacturing. From design principles to practical benefits, let’s explore how this technology can elevate your operations.

What is a Double Layer Roll Forming Machine?

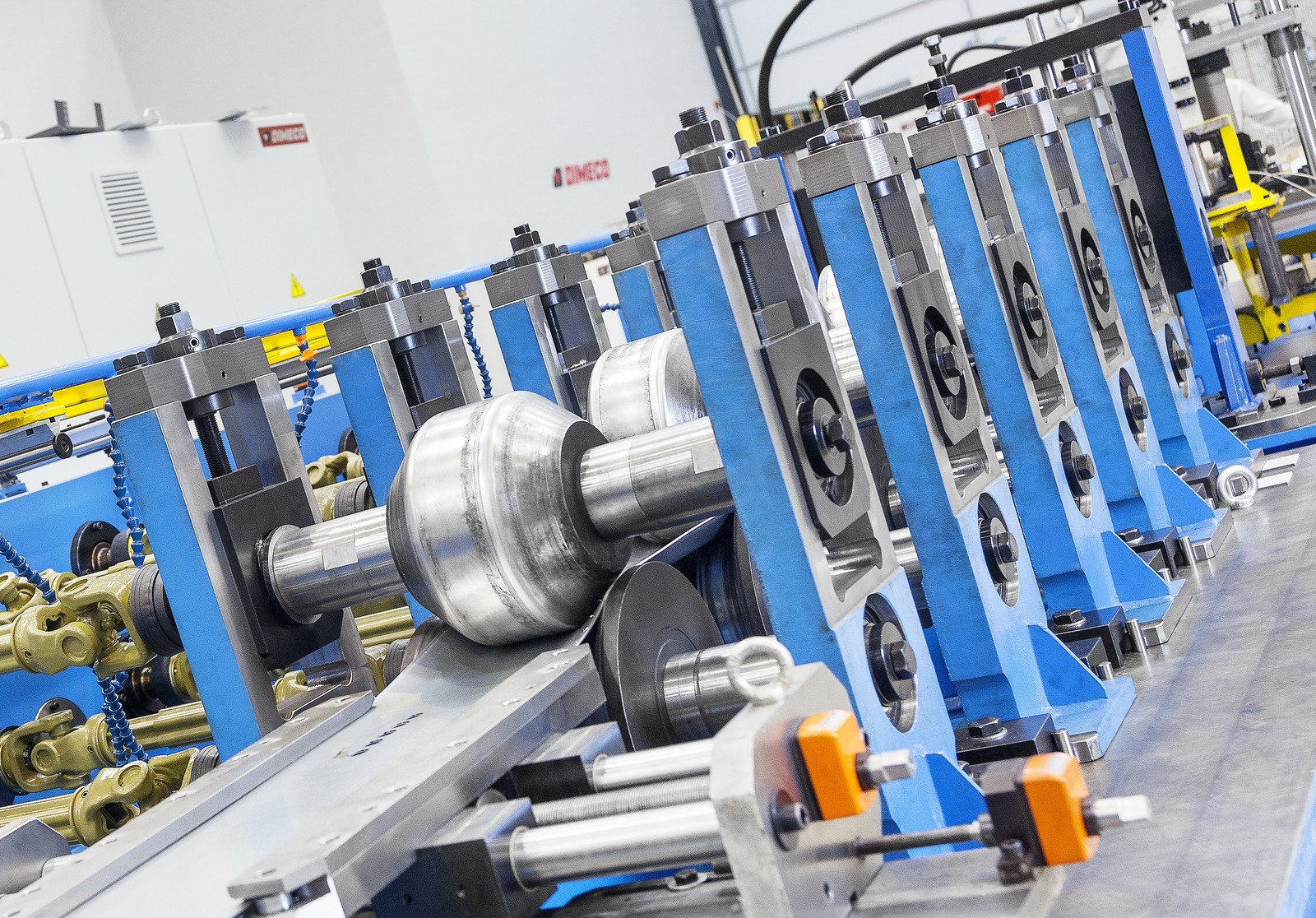

A double layer roll forming machine is a specialized piece of equipment designed to shape metal sheets into desired profiles by passing them through multiple roller stations. Unlike single-layer machines, this type features two layers of rollers stacked vertically, allowing it to form more complex shapes or process two strips simultaneously.

This dual-layer design enhances efficiency by reducing the need for multiple passes and improves accuracy, especially when manufacturing components that require intricate detailing or layered construction. The high-performance gear integrated into these machines ensures smooth operation and consistent output quality.

How Does a Double Layer Roll Forming Machine Work?

The operation of a double layer roll forming machine involves feeding metal strips through two consecutive sets of rollers. Each set shapes the material progressively, bending it incrementally to achieve the final profile. The rollers are precisely engineered and calibrated to maintain tight tolerances throughout the forming process.

The machine’s gear system is critical for synchronizing the upper and lower rollers, guaranteeing that both layers operate in harmony. This synchronization prevents misalignment and distortion, resulting in uniform products that meet rigorous industry standards.

Key Components of a Double Layer Roll Forming Machine

- Rollers: Made from hardened steel, these are responsible for shaping the metal. The double-layer setup means two distinct roller assemblies are working together.

- High-Performance Gear: Ensures smooth, efficient power transmission and precise synchronization between layers.

- Frame: A sturdy structure that supports the entire machine, designed to minimize vibrations and maintain stability.

- Control System: Modern machines are equipped with PLC or CNC controls for automated adjustments and monitoring.

- Uncoiler and Cutter: Uncoils raw metal sheets and cuts finished profiles to length.

Advantages of Using a Double Layer Roll Forming Machine

1. Enhanced Production Efficiency

The double layer roll forming machine can process metal sheets faster by working on two layers or profiles simultaneously. This dual operation reduces production time significantly, making it ideal for high-volume manufacturing environments.

2. Superior Precision and Quality

Thanks to the high-performance gear and advanced roller design, these machines maintain consistent accuracy throughout production. This results in superior product quality, fewer defects, and less material waste.

3. Versatility in Applications

This machine can handle a wide range of materials including steel, aluminum, and copper. It’s used to manufacture roofing panels, automotive parts, door frames, and more, demonstrating its adaptability to diverse industrial needs.

4. Cost-Effective Operation

By combining two forming layers in a single machine, manufacturers save on equipment costs, floor space, and labor. Maintenance is also streamlined due to the machine’s robust construction and efficient gear system.

Applications of Double Layer Roll Forming Machine

The versatility of the double layer roll forming machine makes it invaluable across various industries:

- Construction: Producing roofing sheets, wall panels, and structural components.

- Automotive: Manufacturing chassis parts, bumpers, and reinforcement beams.

- Appliance Manufacturing: Forming frames and panels for refrigerators, ovens, and washing machines.

- Furniture: Creating metal frameworks and support structures.

Each of these industries benefits from the machine’s ability to deliver consistent, high-quality profiles that meet exact specifications.

Selecting the Right Double Layer Roll Forming Machine for Your Business

Choosing the right machine depends on factors such as:

- Material type and thickness

- Desired profile complexity

- Production volume requirements

- Available floor space

- Budget constraints

Engage with reputable suppliers who offer machines with customizable features and reliable after-sales support. The right double layer roll forming machine should balance performance, durability, and ease of operation.

Maintenance Tips for Longevity

To maximize the lifespan and performance of your double layer roll forming machine, consider the following maintenance practices:

- Regularly inspect roller condition and alignment.

- Lubricate gear systems according to manufacturer guidelines.

- Keep the control system updated and calibrated.

- Conduct routine cleaning to prevent debris accumulation.

- Schedule professional servicing periodically.

Proper maintenance not only reduces downtime but also ensures the machine continues to produce high-quality outputs consistently.

Why Choose Roll Forming Machine for Your Double Layer Roll Forming Machine?

At Roll Forming Machine, we specialize in providing cutting-edge forming equipment designed to enhance productivity and precision. Our double layer roll forming machines feature advanced high-performance gears and robust designs tailored to meet the evolving demands of modern industries.

Partnering with us means accessing:

- Expert guidance on machine selection.

- Customizable solutions to fit your production needs.

- Reliable after-sales support and maintenance services.

Elevate your manufacturing capabilities with our state-of-the-art double layer roll forming machine solutions.

Frequently Asked Questions (FAQs)

Q1: What materials can a double layer roll forming machine handle?

A: These machines are versatile and can process various metals, including steel, aluminum, and copper sheets, typically within specified thickness ranges depending on the model.

Q2: How does the double layer design improve efficiency?

A: By working on two layers or profiles simultaneously, the machine reduces processing time and increases output without compromising precision.

Q3: Can the double layer roll forming machine be customized?

A: Yes, many manufacturers offer customizable configurations to accommodate different profile designs, material specifications, and production volumes.

Conclusion

The double layer roll forming machine represents a leap forward in metal forming technology, combining efficiency, precision, and versatility in one high-performance gear system. For manufacturers aiming to boost productivity while maintaining top-quality output, investing in this technology is a strategic move. Explore our homepage now to stay ahead in the digital world.